Introducing Guangxi Donglan Co., Ltd Established in 2021, this dynamic company…

Guangxi Donglan’s Innovative Technology: Developing and Optimizing the Process for Eco-Friendly BIPB Crosslinking Agents

Introduction to the Process

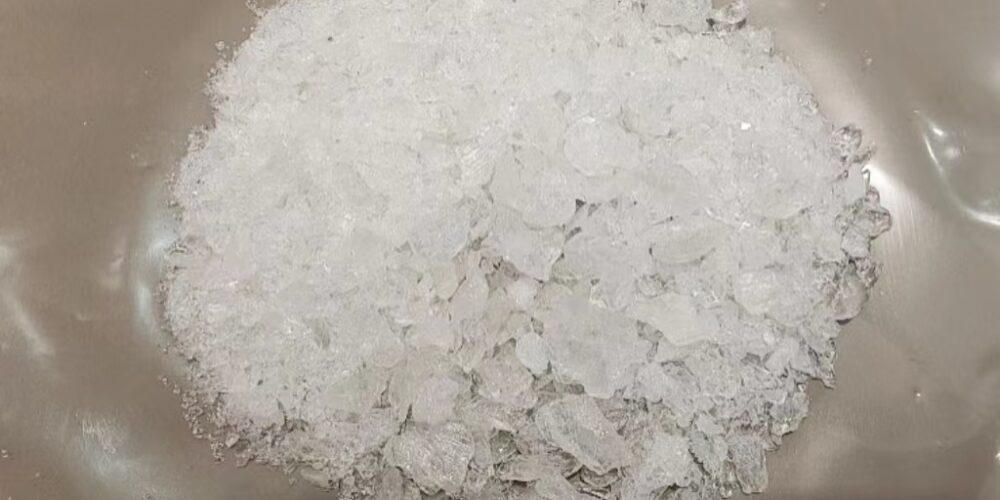

At Guangxi Donglan, we’re pioneering the creation of a new eco-friendly crosslinking agent, the BIPB series, through a meticulously designed process. Starting with diisopropylbenzene and tertiary-butyl hydroperoxide as raw materials, we add sulfuric acid and sodium perchlorate monohydrate as catalysts. The production involves key steps: oxidation reactions, reduction reactions, crystallization centrifugation, condensation reactions, drying, pelletizing, and packaging. This comprehensive approach ensures the high quality and environmental friendliness of our BIPB series products.

Key Technological Innovations

Our groundbreaking work includes the development of a novel process for preparing eco-friendly crosslinking agent catalysts. We achieve this through the condensation reaction of mDC with TBHP to produce mBIPB. The process involves adding approximately 5% to 10% of the total reactant mass 70%-H2SO4 and adding No. 8 auxiliary catalytic material. The feeding ratio is diisopropylbenzene alcohol DC to No. 8 auxiliary catalyst = 100:30~60 (by weight); we control the reaction temperature between 30 to 55°C and maintain the reaction time within 30 to 50 minutes.

Intermediate Preparation Process

During the oxidation reaction, diisopropylbenzene reacts with oxygen in an alkaline environment to form the peroxide products MHP and DHP. We ensure the molar ratio during the reduction reaction between the oxidizing liquid and a 10% Na2S aqueous solution to favor the reduction of DHP to mDC, adjust the system’s pH value to minimize the generation of sulfur oxides and achieve high-purity products through dual crystallization. The components’ differing solubilities in certain solvents allow for the reuse and recycling of MHP and MC. Process coupling and improvements in the oxidation tower enable continuous operation, increasing output and stability.

Innovative Features

We have developed a novel production system for crosslinking agents that integrates crystallization, washing, filtration, and drying processes. This fully sealed system prevents product contact with air or operators, reducing accidents and environmental pollution. Utilizing vacuum cooling for crystallization and high-temperature drying allows for continuous and compressing operation time. Automation throughout the entire process significantly reduces the risks associated with manual operations and enhances production capacity.

Further innovations include the development of automatic backwashing filters, feeding devices, and oil-water separation pretreatment devices. These advancements ensure controlled feeding speeds, uniformity in material addition, and savings in water and raw materials, guaranteeing continuous production, enhancing efficiency, and improving product quality.

At Guangxi Donglan, we’re not just creating chemicals but crafting eco-friendly industrial processes’ future. Through our commitment to innovation and sustainability, we strive to meet our customers’ evolving needs while protecting our planet for future generations.

Contact Us

If you are interested in our company’s products, please don’t hesitate to contact us via email at info@dladvanchem.com. Our team is dedicated to providing you with all the information you need and answering any queries you may have about our wide range of products. Whether you’re looking for specific product details, pricing information, or any other assistance, we’re here to help.

This Post Has 0 Comments