Introducing Guangxi Donglan Co., Ltd Established in 2021, this dynamic company…

The Rising Star in Crosslinking Agents: BIPB vs. DCP

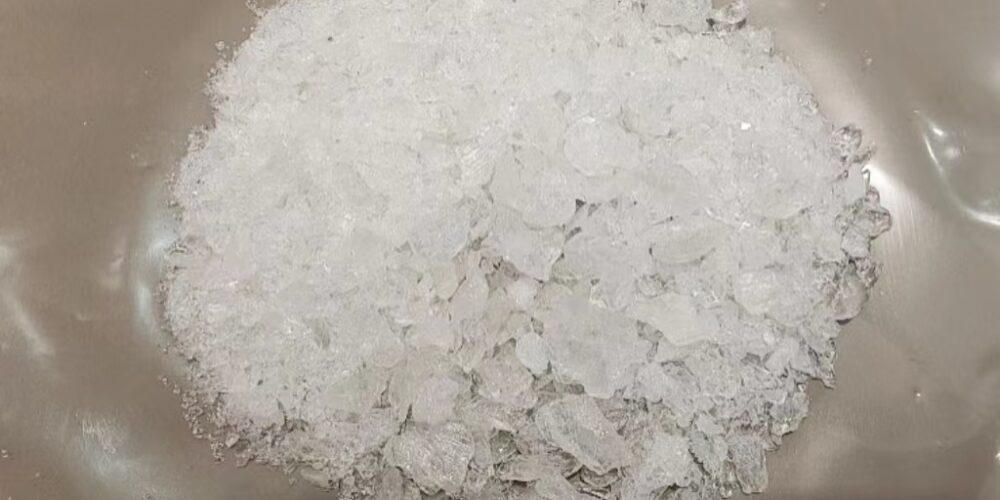

The continuous search for safer, more efficient, and eco-friendly substances is ongoing in the dynamic realm of materials science. This pursuit has highlighted BIPB (Bis(tert-butylperoxy isopropyl)benzene) as a compelling alternative to the conventional crosslinking agent, DCP (Dicumyl Peroxide). These chemicals are pivotal in crosslinking, significantly improving rubber and plastics’ mechanical attributes. BIPB, with its enhanced performance and green credentials, coupled with a more profound comprehension of the thermal decomposition mechanisms of both agents, is redefining industry benchmarks and steering the sector toward a greener future.

High Efficiency and Improved Properties

One of the standout benefits of BIPB compared to DCP lies in its superior crosslinking efficiency. This advantage not only decreases the amount needed for equivalent levels of crosslinking but also drives down costs and elevates the end product’s performance. Materials that crosslink with BIPB demonstrate enhanced thermal stability, improved flexibility at lower temperatures, and better compression set characteristics. These enhancements are vital for applications requiring materials to maintain performance and structural integrity under severe conditions.

Environmental Friendliness and Safety

In an era where the pursuit of environmental sustainability is not merely a preference but a mandate, BIPB stands out as a greener choice. In contrast to DCP, BIPB is odorless, rendering it more suitable for integration into consumer products, especially those intended for direct contact with the skin. This characteristic, coupled with its adherence to rigorous environmental standards, particularly within the European Union, where restrictions on DCP usage in everyday items like shoes are in place, elevates its appeal. BIPB’s eco-friendly profile is further enhanced by its alignment with strict regulatory requirements, underscoring its superiority as a sustainable alternative in the global market.

The Thermal Decomposition Process: A Closer Look

The environmental and health concerns linked to DCP primarily stem from its decomposition under heat. This process breaks down its peroxy bond, leading to the formation of cumyl oxy radicals. These radicals can further break down into methyl radicals and acetophenone—a compound known for its unpleasant smell and potential harm to human health. This highlights that the odor associated with DCP is a fundamental aspect of its chemical makeup rather than a result of impurities or residual substances, clarifying that achieving higher purity levels would not mitigate the odor issue.

In contrast, the thermal decomposition of BIPB results in the creation of alkyl radicals, which then interact with the surrounding polymeric matrix. The by-products from the BIPB crosslinking process include methane (CH4) and other volatile substances such as acetone and tert-butanol. These compounds are more prone to evaporation, leaving behind odorless solid by-products. Consequently, products crosslinked with BIPB exhibit little to no odor, making it a more suitable option for applications where odor is a concern. This distinction makes BIPB a significantly more attractive choice for use in environments sensitive to smell.

Addressing Market Imperatives

The transition towards BIPB transcends its distinguished properties and environmental merits, aligning with the evolving market demand dynamics. A burgeoning call from consumers and regulatory bodies alike for materials encapsulating safety, sustainability, and superior quality has been instrumental. The regulatory limitations placed on DCP across specific applications have propelled BIPB to the forefront as the crosslinking agent of choice for manufacturers striving to meet these advanced criteria and regulations. Beyond its conventional applications in high-voltage cables and ubiquitous rubber and plastic products, BIPB’s adaptability underpins its incorporation into manufacturing furniture and toys alongside a diverse spectrum of other industries. This broad applicability accentuates the pivotal role of BIPB as an agile crosslinking agent, adeptly navigating the complex requirements of contemporary manufacturing processes.

Fundamentally, BIPB signifies a profound advancement within the realm of crosslinking agents. Distinguished by its superior efficiency, refined material properties, ecological harmony, and odorless release during and post-processing, BIPB emerges as a robust substitute for DCP. As the momentum shifts towards environmentally friendly and operationally effective materials, the significance of BIPB is set to surge, marking a critical juncture towards a more sustainable future in material science. The adoption of BIPB reflects an industry’s commitment to pioneering innovation and its engagement with the escalating demands for safe and environmentally responsible products.

Contact Us

If you are interested in our company’s products, please don’t hesitate to contact us via email at info@dladvanchem.com. Our team is dedicated to providing you with all the information you need and answering any queries you may have about our wide range of products. Whether you’re looking for specific product details, pricing information, or any other assistance, we’re here to help.

This Post Has 0 Comments